About us

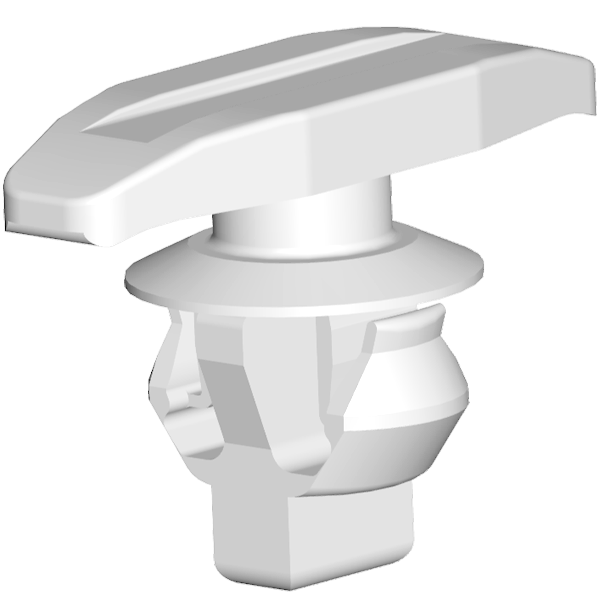

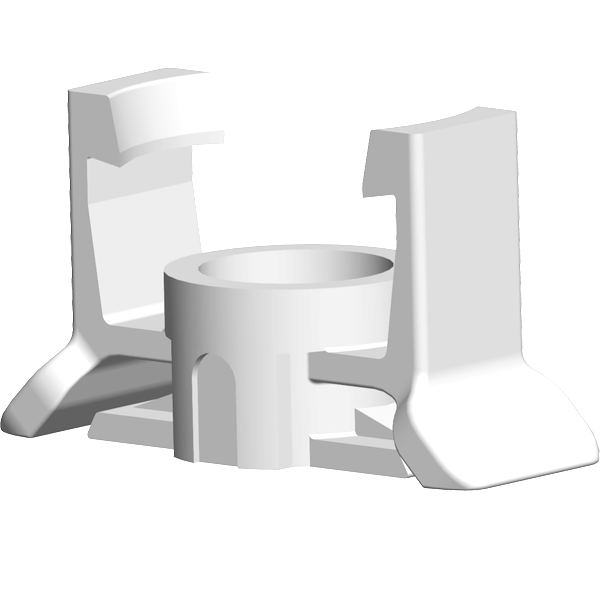

Our main activity is

production and assembly

technical articles

from plastic.

We started in Koniaków in 1992 with production of footwear components. Then we began to cooperate with automotive industry customers in 1996.

In the year 2005 our production moved to a rented production hall in Ustroń and ISO 9001 certification was accredited to us. The production hall was purchased in 2009. We acquired the IATF 16949:2016 certificate in 2018.

The company's development led us to decide to buy a plant in Skoczów in 2016, where we finally moved all production in 2019.

In response to the challenges of the modern world and ecology, taking into account the activities for environmental protection and pollution prevention, in 2021 we implemented an Environmental Management System in accordance with the ISO 14001:2015 standard.

We currently employ over 150 people.

In the year 2005 our production moved to a rented production hall in Ustroń and ISO 9001 certification was accredited to us. The production hall was purchased in 2009. We acquired the IATF 16949:2016 certificate in 2018.

The company's development led us to decide to buy a plant in Skoczów in 2016, where we finally moved all production in 2019.

In response to the challenges of the modern world and ecology, taking into account the activities for environmental protection and pollution prevention, in 2021 we implemented an Environmental Management System in accordance with the ISO 14001:2015 standard.

We currently employ over 150 people.

Offer

We offer our clients:

Thermoplastic

Thermoplasticinjection

Overmolding

Overmoldingmetal or plastic

elements

Assembling of

Assembling ofmetal or plastic

elements

2K injection

2K injection Cooperation during

Cooperation duringa product design process

Management of

Management ofinjection moulds production

3D scanning

3D scanning Production of

Production ofprototype elements

Coating and tampo

Coating and tampoprinting (outsourcing)

Our company possesses machines from 25–1400 T clamp force.

The machinery is being constantly modified and modernised.

Quality

Techniplast's goal is

production and delivery on

time of high quality products

as required

Customer at the same time

continuous development

and improving the company.

- Since 2003, the company has a Quality Management System compliant with ISO 9001: 2008. In 2018, a Quality Management System compliant with the IATF 16949:2016 standard was implemented.

- In order to meet our customers’ rising expectations and ensure the highest quality of our products, Techniplast has been permanently and continuously raising the staff’s quality awareness.

- Pursuing our objectives, we have created a complex project management process as well as we have been continuously improving the organisation and quality systems.

- We are continuously raising our staff’s qualifications through a range of trainings in order to meet our Customers’ demands.

- We perform maintenance and minor repairs of injection moulds in our internal tool shop, as well as we manage the appropriate modifications to be implemented at our external contractors..

- Techniplast Sp. z o.o. has been subject to regular quality system audits.

Clients

Among our customers are:

Our group

Contact

You can find us:

ARTYKUŁY TECHNICZNE Z TWORZYW SZTUCZNYCH

ARTYKUŁY TECHNICZNE Z TWORZYW SZTUCZNYCH  NARZĘDZIOWNIA I AUTOMATYZACJA

NARZĘDZIOWNIA I AUTOMATYZACJA